News Story

Al-Obaid, Adomaitis publish renewable energy algorithm in Royal Society of Chemistry journal

In a time of climate change, hydrogen-based energy is a possibility for a world looking to replace fossil fuels with more environmentally friendly sources. Currently, most hydrogen production relies on fossil fuels, but it is possible to produce hydrogen in greener ways. For example, hydrogen can be produced using a photovoltaic-electrolysis-battery system that uses renewable sources such as wind and solar to power water electrolysis.

This process is capable of producing extremely pure hydrogen suitable for running fuel cell vehicles. Despite this method being understood and available for more than 200 years, currently less than 4% of hydrogen is produced in this way. Researchers are working to optimize the design, optimal size and operation of sustainable hydrogen production systems—particularly those that take advantage of recent advances in and greater affordability of photovoltaic materials.

In “Optimal design of a coupled photovoltaic–electrolysis-battery system for hydrogen generation,” a new paper published in in the Royal Society of Chemistry journal Sustainable Energy & Fuels, alumna Aisha Al-Obaid (ChBE PhD 2019) and Professor Raymond Adomaitis (ChBE/ISR) have developed a computational algorithm that models an integrated photovoltaic–electrolysis-battery system and can identify the optimal size a system should be.

Al-Obaid is an assistant professor in the Department of Chemical Engineering at Kuwait University. Adomaitis was her PhD advisor at Maryland.

In testing, this algorithm evaluated more than 2 million possible sizing combinations. The model’s simulation results yielded 170 sizes that fell within an acceptable range. From these, 10 were chosen as a set of “Pareto front” optimal solutions, where each objective is considered “equally good.” The researchers found that optimizing the system’s cost and hydrogen production rate implicitly ensured a minimized levelized cost of energy for the system.

How an integrated PV–electrolysis-battery system works

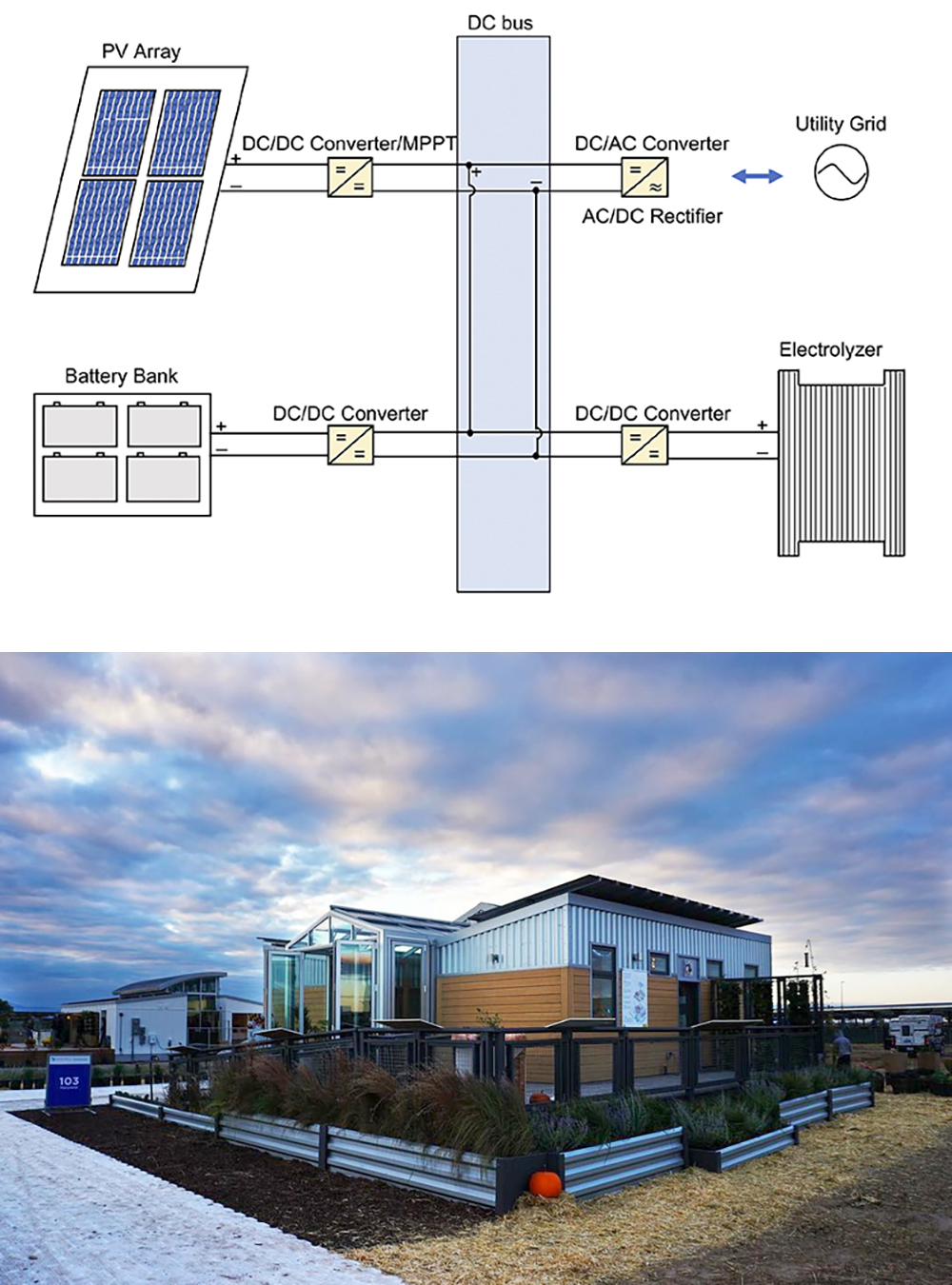

Photovoltaic (PV) modules are connected solar cells that absorb energy from sunlight and convert it into electrical energy through semiconducting materials. In an integrated system, these modules provide the power that runs the electrolyzer, a sub-system that uses electricity to create hydrogen gas by breaking water into hydrogen and oxygen. Excess power generated by the PV modules charges the battery. At night, the battery provides the power necessary to ensure the electrolyzer’s uninterrupted operation.

The system is connected to the electric grid to ensure the electrolyzer keeps running during seasonal weather variations. When there is insufficient generation of PV-based electricity—for example if there is a prolonged period of cloudiness—the grid supplies power for the electrolyzer and battery charging. When the PV modules generate excess power, it can be sold to the grid. To achieve maximum design and operation sustainability, the coupled system is required to meet net-zero grid energy throughout the year.

About the model developed in the paper

Al-Obaid and Adomaitis’s analysis goal was to identify the optimal system configuration that could maximize hydrogen production rate, minimize levelized cost of energy and total system cost, and target a net-zero grid energy operation.

The clear mathematical model they developed can calculate the global irradiance (amount of energy from sunlight) falling on a PV module surface, given its orientation, location, and time of the day.

Unlike research that uses only a 24-hour period to simulate and analyze the hybrid system, or assumes a fixed averaged value of global irradiance, this model uses hourly incremented calculations to simulate the coupled system for an entire year; including both diurnal and seasonal weather variations.

Testing the model with Maryland’s Solar Decathlon houses

The researchers used this model to effectively forecast the energy generation of a solar-powered house in Colorado during the 10-day US Department of Energy Solar Decathlon competition in 2017.

Adomaitis led the team that designed and built the University of Maryland entry, “ReACTHouse.” The ability of the model to accurately forecast future energy generation was a key factor behind the Maryland team achieving nearly perfect net-zero electrical power performance. ReACTHouse took second place overall and first among US teams.

The model also was validated by applying it to and testing it on a previous Maryland Solar Decathlon entry, 2007’s LEAFHouse, which is displayed on campus in College Park. The researchers were able to compare the simulation's prediction of house performance to the actual measured LEAFHouse power generation data.

Future possibilities

The flexible computational platform can be extended to more complex hybrid systems. For instance, wind power can be added to promote further sustainability and drive the system to off-grid limits. Additionally, the model could be modified to evaluate the influence of incorporating environmental measures in the optimization problem, such as minimizing carbon dioxide emissions. Another possibility is the inclusion of post-production stages in the simulation, such as hydrogen purification, storage, conditioning, and distribution to the end user, which offer a broader perspective and can be nicely integrated with the current study to form a hydrogen supply chain network design problem. The model can also accommodate reliability, environmental impact, and safety measures for assessment.

Published March 2, 2023