News Story

UMERC Researchers Came Out in Force at the ARPA-E Summit

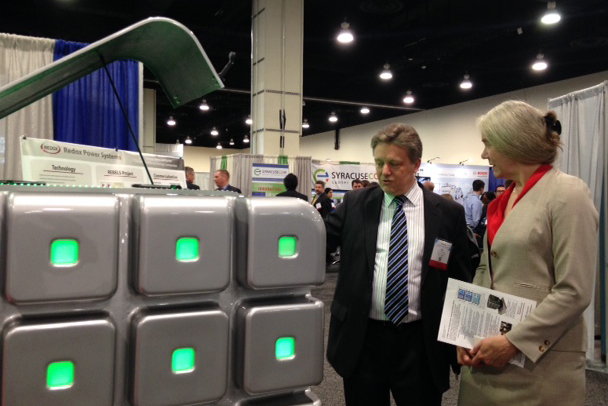

Newly appointed ARPA-E director and UMD Physics faculty, Dr. Ellen Williams discusses Redox Fuel Cell technology with UMERC Director, Dr. Eric Wachsman.

Last week, the Advanced Research Project Agency- Energy (ARPA-E) hosted its sixth annual Energy Innovation Summit at the Gaylord National Harbor Convention Center. The summit brings together experts from different technical disciplines and professional communities to think about energy challenges in new and innovative ways. The aim of ARPA-E is to move transformational energy technologies out of the lab and into the market. The summit combined traditional conference presentations with the Technology Showcase, at which researchers, companies, and government labs displayed their innovative energy technologies. As ARPA-E awardees, UMERC professors Wachsman, Wang, Takeuchi, and Ohadi were each granted the opportunity to display their winning technologies at the Technology Showcase. More about their technologies below:

Eric Wachsman, Liangbing Hu, and Dr. Thangadurai (University of Calgary), are developing Safe, Low-Cost, High-Energy Density, Solid-State Li-Ion Batteries. This technology applies revolutionary advances in solid-state-ionics and conventional ceramic fabrication techniques to develop high-energy-density, low-cost, all solid-state batteries. The all solid-state structure of this technology provides revolutionary dimensional tolerance and mechanical strength, decreasing packaging requirements and system weight. Ultimately this technology will dramatically reduce manufacturing costs using scalable, ceramic fabrication techniques.

Chunsheng Wang is developing Hybridized Md2+/H+ Aqueous Battery for Vehicle Electrification, an innovative battery technology that will not only be lighter, safer, and cheaper than current technology. The water-based magnesium and hydrogen chemistry improves energy density of the batteries, which will be built from safe, inexpensive materials, reducing the cost of battery management or replacement, improving reliability, and this will allow the batteries to operate across a wide range of temperatures.

Ichiro Takeuchi is developing an energy-efficient Thermoelastic Cooling system that eliminates the need for synthetic refrigerants that are harmful to the environment. Thermoelastic cooling systems use a solid-state material – an elastic shape memory metal alloy – as a refrigerant and a solid-to-solid phase transformation to absorb or release heat. This technology alternately absorbs or creates heat in much the same way as a vapor compression system, but with significantly less energy and a smaller operational footprint.

Michael Ohadi's group presented their results on A Case Study on the Impact of Additive Manufacturing for Heat/Mass Transfer Equipment used for Power Production. The long-term goal of this technology is to reduce or eliminate water consumption in traditional thermoelectric power plant cooling systems. Ultimately the research team will select two novel heat exchanger designs that can radically enhance air-side heat transfer and create and test two 1kW prototypes.

Redox Power Systems, the fuel cell company that spun out of UMERC also presented at ARPA-E, displaying their “cube” fuel cell designed for distributed power generation systems. Their Low-Temperature Solid Oxide Fuel Cells for Transformational Energy Conversion maintain high power density and enable faster cycling, with dramatically lower operating temperature of 400 degrees C.

Two UMD projects were awarded funding by ARPA-E under the Delivering Efficient Local Thermal Amenities (DELTA) program at the end of 2014, and were not able to present this year. Therefore we look forward to having an even larger UMERC contingent at next year’s summit!

The two DELTA projects were awarded to Dr. YuHuang Wang and Dr. Reinhard Radermacher’s teams for “Personal HVAC Systems”.

YuHuang Wang’s project, Meta-Cooling Textile with Synergetic Infrared Radiation and Air Convection for Bidirectional Thermoregulation will develop a thermally responsive fabric that extends the skin’s thermoregulation ability to maintain comfort in hotter or cooler office settings.

Reinhard Radermacher’s project, Robotic Personal Conditioning Device, will develop a mobile platform to provide personalized cooling to individuals. This technology will contain a small, battery-powered, high-efficiency vapor compression heat pump to provide localized air conditioning as needed during the day while dumping stored heat and recharging batteries at night.

Published February 16, 2015